Web Menu

Product Search

Exit Menu

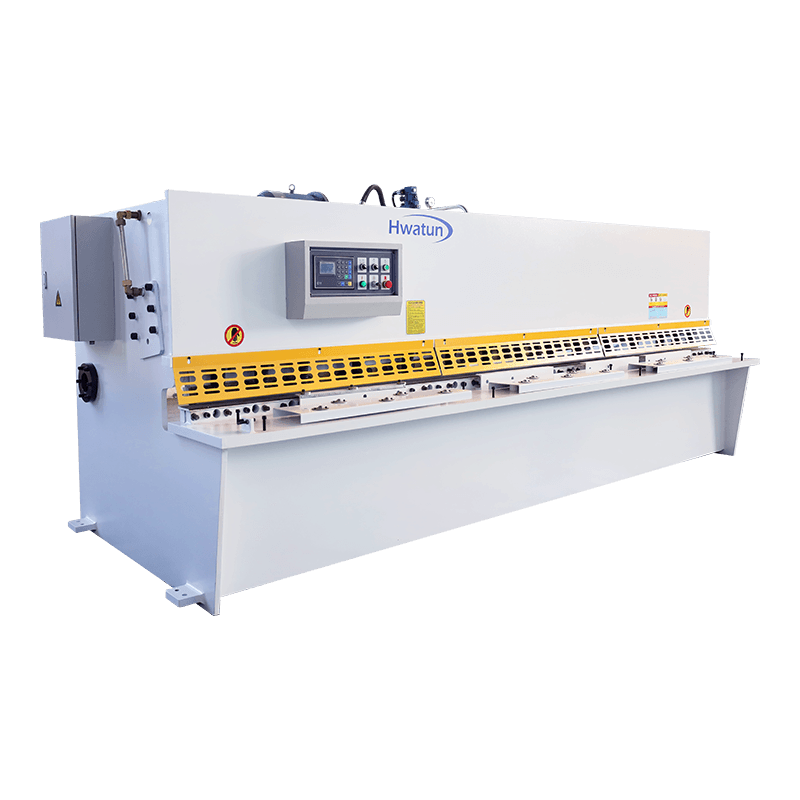

What is the solution when SHEARING MACHINE encounters uneven cutting and other problems?

When a shearing machine encounters uneven cutting or other related problems, it can significantly impact the quality of the finished product and overall operational efficiency. Here’s a detailed look at the solutions for uneven cutting and other common issues:

Before addressing the problem, it’s essential to identify the root causes.

Over time, the blades can become dull or chipped, leading to uneven cuts.If the upper and lower blades are not aligned properly, it can result in inconsistent cutting.Variations in material thickness can cause uneven cutting, especially if not accounted for.Too fast or too slow cutting can affect the quality of the cut.If the back gauge is not set correctly, it can lead to inconsistent lengths and angles in the cuts.

Periodically check the condition of the blades for signs of wear or damage.Dull blades should be sharpened to restore cutting efficiency.If blades are excessively worn or damaged, they should be replaced with new ones to ensure clean cuts.

Use a dial gauge or laser alignment tool to ensure that the upper and lower blades are properly aligned.If misalignment is detected, adjust the machine settings according to the manufacturer’s specifications to realign the blades.

Use calipers or other measuring devices to check the thickness of the material before cutting.Group materials of similar thickness together to minimize variability during the cutting process.

Consult the machine’s manual to determine the recommended cutting speed and feed rate for different materials.Conduct test cuts with various settings to find the optimal speed and feed rate that yield the best results.

Ensure that the back gauge is calibrated correctly to provide consistent lengths and angles.If necessary, adjust the back gauge position and verify that it is functioning properly.

Ensure that the material is fed correctly into the machine and that there are no obstructions.If jamming occurs, stop the machine and carefully remove the jammed material before resuming operation.Inspect the machine for loose components or worn parts. Tighten any loose screws and replace worn parts as needed.Ensure that all moving parts are properly lubricated to reduce friction and noise.

Regularly monitor and refill hydraulic fluid as necessary to maintain optimal operation.Look for any signs of hydraulic leaks and repair them promptly to prevent pressure loss.

Inspect electrical connections for any loose or damaged wires.If the control system is malfunctioning, it may need to be reprogrammed or reset to restore normal function.

Establish a regular maintenance schedule that includes inspections, cleaning, and lubrication. Keeping the machine in optimal condition can prevent many issues from arising.

Provide proper training for operators on how to use the machine correctly, including how to set up cuts and adjust for different materials. Well-trained operators are less likely to encounter problems and more capable of troubleshooting when issues arise.

When a shearing machine encounters uneven cutting and other issues, it is crucial to identify the root causes and implement effective solutions. By maintaining the machine properly, ensuring correct alignment and settings, and providing adequate operator training, many problems can be prevented or resolved quickly. Regular maintenance and monitoring can lead to improved efficiency, reduced downtime, and higher-quality outputs in the manufacturing process.

News categories

Product categories

Related Products

+86-159 5138 1316

+86-159 5138 1316 +86 180 6819 3096

+86 180 6819 3096 [email protected]

[email protected] Group 4, Xinba Village, Binhai New Area (jiaoxie Town), Laoba Port, Nantong City, Jiangsu, China.

Group 4, Xinba Village, Binhai New Area (jiaoxie Town), Laoba Port, Nantong City, Jiangsu, China.

Copyright © Nantong Hwatun Heavy Machine Tool Co., Ltd. All Rights Reserved.

Eng

Eng  简体中文

简体中文 Español

Español русский

русский