The WC67K Torsion-Sync CNC Press Brake represents the pinnacle of modern bending technology, offering a blend of cutting-edge design, precision engineering, and user-friendly features. Designed specifically for torsion axis synchronous bending, this press brake is ideal for both entry-level and advanced users seeking a reliable and high-performance solution.

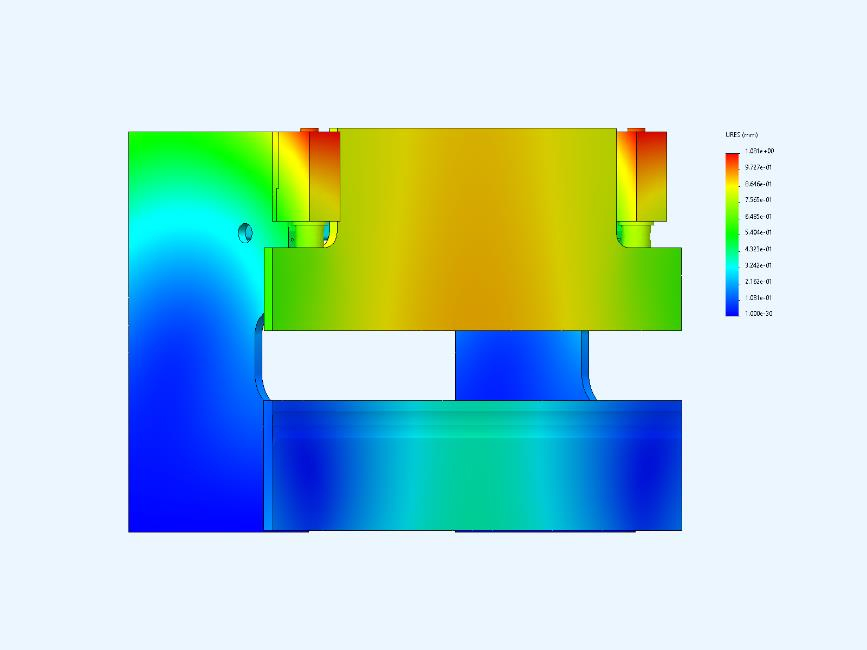

Exceptional Design and Build Quality

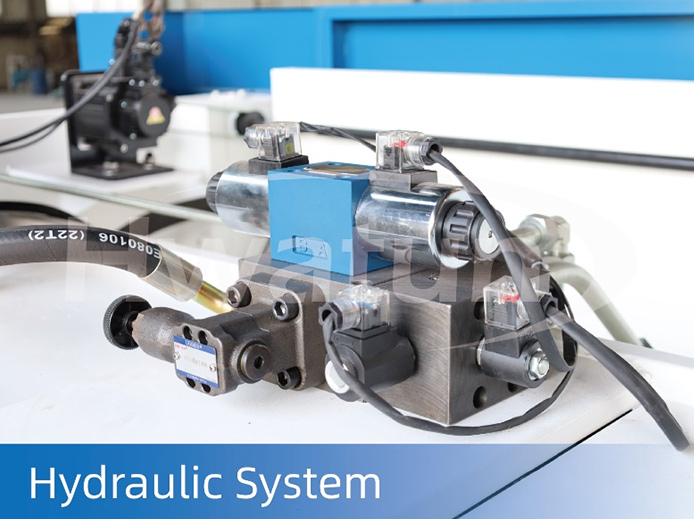

The WC67K series boasts an advanced industrial design with an integrated welded frame, ensuring exceptional stability and durability. The machine's robust construction is further enhanced through CNC machining center processing, which guarantees high precision and long-lasting performance. The torsion axis synchronous system employed in this press brake provides accurate and consistent bending results, making it a valuable addition to any workshop or manufacturing facility.

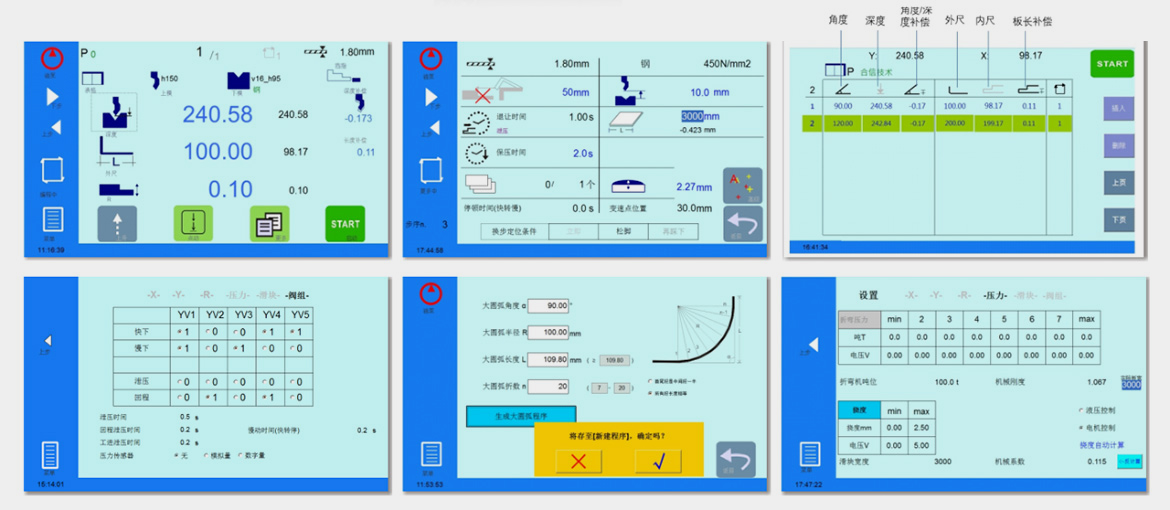

Advanced CNC System

At the heart of the WC67K is the COTRUST TP10 CNC system, a fully functional and sophisticated control unit specifically engineered for torsion synchro press brake machines. The TP10 CNC system is equipped with a 10-inch true color touch screen, offering an intuitive and easy-to-use interface for operators. Its PLC control ensures stable and reliable performance, while the CANopen bus communication control facilitates fast communication and precise positioning.

The TP10 CNC system supports up to 350 programs with 24 steps each, providing extensive programming flexibility to handle a variety of bending tasks. It also includes a user-friendly mold library management function, making mold selection and configuration straightforward. The system’s menu interface or table programming options cater to different user preferences, enhancing operational convenience.

Automated Precision and Flexibility

The WC67K press brake is designed to streamline operations with several automated functions. It features an automatic backstop surrender function, which adjusts the backstop position during bending operations to ensure accuracy and safety. The system also automatically calculates pressure, depth, angle, deflection, and plate width compensation, reducing manual adjustments and minimizing errors.

One of the standout features of the TP10 CNC system is its ability to perform infinite step bending through its link program function. This capability allows for the execution of complex bending sequences with ease, making it ideal for producing intricate parts and components.

Versatility and Customization

The WC67K series offers versatility in tooling and operation. It supports up to 30 upper punches and 60 lower dies for storage capacity, accommodating a wide range of bending tools and dies. Optional functions, such as bridge functions and advanced compensation algorithms, are available for customization, allowing users to tailor the machine to their specific needs and applications.

The system's user-centric design also includes a quick access program page for easy and rapid launching of programs, further enhancing operational efficiency.

Compliance and Certification

The WC67K Torsion-Sync CNC Press Brake is CE and RoHS certified, meeting stringent international standards for safety and environmental protection. This certification underscores the machine’s commitment to quality and regulatory compliance, providing users with confidence in their investment.

The WC67K Torsion-Sync CNC Press Brake combines cutting-edge technology, robust construction, and advanced automation to deliver a high-precision bending solution. With its user-friendly features and customizable options, it is an excellent choice for those seeking a reliable and versatile press brake for their manufacturing needs.

Eng

Eng  简体中文

简体中文 Español

Español русский

русский