Web Menu

Product Search

Exit Menu

Precision CNC Machine Suppliers

Nantong Hwatun Heavy Machine Tool Co., Ltd. is China precision CNC machine suppliers and precision CNC machine company, a key enterprise in the forging machinery industry, specializing in the production of "Huaduan" brand series shearing machines, bending machines, plate rolling machines, hydraulic presses, uncoiling, leveling and shearing production lines, etc.

Hwatun Machine Tool is integrating advanced technologies at home and abroad with advanced awareness, new concepts, and innovative spirit, and continuously developing industry products, laying a solid foundation for "Huaduan" to build a well-known brand in the world forging industry.

CNC Press Brake

A CNC bending machine employs computer numerical control (CNC) technology to accurately bend metal sheets, making it indispensable in industries such as automotive, aerospace, and construction. The machine features a sturdy frame, a worktable, and bending tools, with hydraulic or electric actuators providing the necessary force for bending. Operators program the machine with specific bending instructions, ensuring high precision and repeatability. This automation reduces manual labor, minimizes errors, and enhances productivity, allowing for the creation of complex components with exacting tolerances.

-

EH8 Electro-Hydraulic Servo Bending Machine

Ready to take your bending operations to the next level? The EH8 Series is here for you! Built with a sturdier frame and equipped with the cutting-edge Delem DA53T system (with options for other Delem...Read More -

EH6 Series Electro-Hydraulic Servo Bending Machine

Looking for an affordable and reliable electro-hydraulic Servo bending machine? The EH6 Series is just what you need! With the easy-to-use SCS700 CNC system and a standard electric compensation workta...Read More -

WC67K Torsion-Sync CNC Press Brake

Want to say goodbye to NC bending machines? The WC67K series of CNC torsion bar bending machines is the perfect entry-level choice for CNC bending.Equipped with the TP10 CNC system and an electric com...Read More

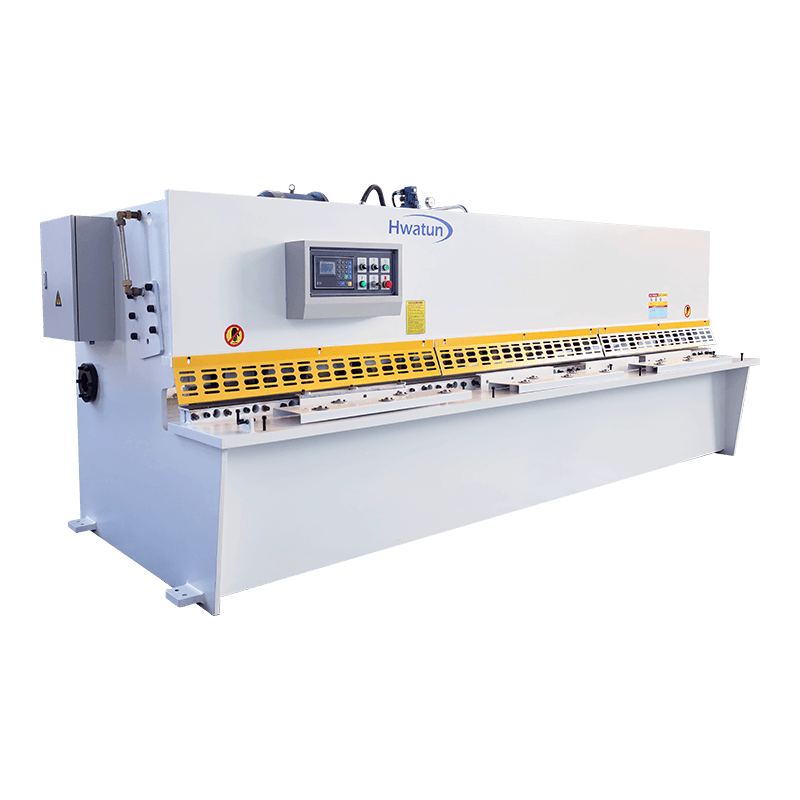

Shearing Machine

A hydraulic shearing machine is a robust cutting tool used in the metal fabrication industry to shear sheets and plates of metal with precision and efficiency. The machine operates using hydraulic power to drive a moving blade down onto a fixed blade, cutting the metal along a straight line. Its key components include a sturdy frame, a worktable, upper and lower blades, and a hydraulic system comprising cylinders, pumps, and a control unit.

The hydraulic system provides a high level of force and allows for smooth, controlled cutting operations. Operators can adjust the blade gap and cutting angle to accommodate different materials and thicknesses, ensuring clean, accurate cuts. The machine’s control panel allows for easy operation, with features to set and adjust cutting parameters quickly.

Hydraulic shearing machines are favored in industries such as automotive, aerospace, and construction for their ability to handle heavy-duty cutting tasks and produce high-quality, precise cuts with minimal distortion. The hydraulic power system also contributes to the machine's reliability and durability, making it a valuable asset in high-volume production settings.

-

QC11Y CNC Hydraulic Guillotine Shearing Machine

Are you looking for a precise and effortless guillotine shear that can cut entire metal plates thicker than 10mm?Our QC11Y Series Hydraulic Guillotine Shear is perfect for you. The QC11Y Series Shear ...Read More -

QC12Y CNC Hydraulic Swing Beam Shearing Machine

Are you looking for a precise and user-friendly metal sheet cutting machine? Our QC12Y series shears are exactly what you need. The QC12Y series shears are equipped with advanced technology, a standar...Read More

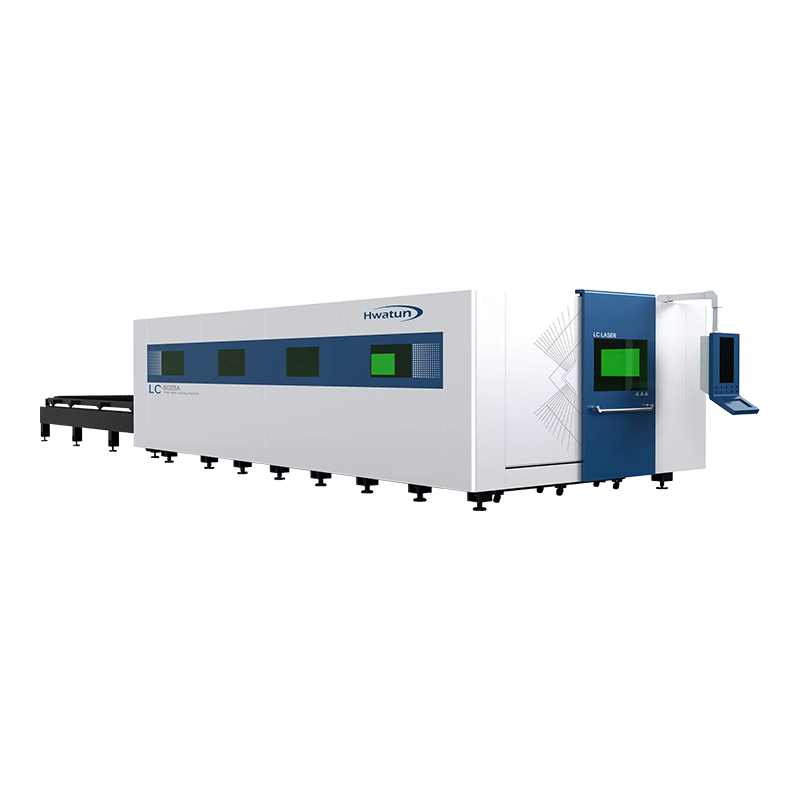

CNC Laser Cutting Machine

A CNC laser cutting machine for sheet metal processing is an advanced tool engineered to deliver precise and efficient cutting and engraving of sheet metal. Utilizing a high-powered laser beam, the machine operates under the control of a computer numerical control (CNC) system, allowing for the execution of intricate cuts and detailed designs. The key components of this machine include a laser source, a cutting head with focusing optics, a worktable, and a CNC controller.

The CNC system meticulously manages the laser's movement and intensity, facilitating the accurate cutting of complex shapes and patterns. Operators can program cutting paths, adjust settings, and oversee the process in real-time via the machine's user-friendly interface, ensuring optimal performance.

CNC laser cutting machines for sheet metal processing find extensive applications in industries like automotive, aerospace, electronics, and manufacturing. They provide significant benefits such as high cutting speeds, minimal material waste, and the capability to produce clean, precise cuts with smooth edges. These machines can handle a variety of metals, including steel, aluminum, and titanium, making them highly versatile and essential in contemporary metal fabrication. The automation and precision of CNC laser cutting machines minimize manual labor, enhance production efficiency, and enable the fabrication of detailed and complex components with tight tolerances.

-

Single-table Fiber Optic Laser Cutting Machine

Incorporating the electric cabinet and laser into the machine streamlines the process by eliminating the need for additional disassembly and reassembly, preventing any potential contamination of the o...Read More -

Double-table Fiber Optic Laser Cutting Machine

This fiber laser cutting machine been worked to help you cut several metal sheet, such as stainless steel, aluminum alloy sheet, carbon steel sheet copper etc.and it has the exchange platform for you ...Read More

Contact Us

Eng

Eng  简体中文

简体中文 Español

Español русский

русский